Interrogating the Design of a Core Shell Microparticle 1

Interrogating the Design of a Core Shell Microparticle 1

William Thomas Rothwell

Koch Institute at MIT

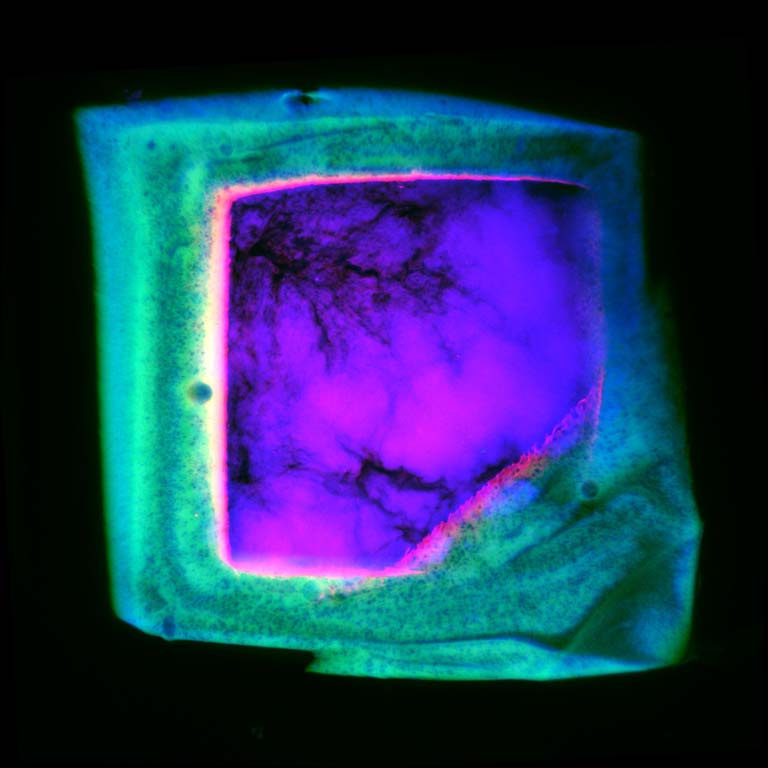

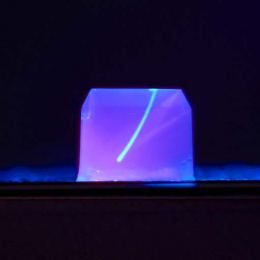

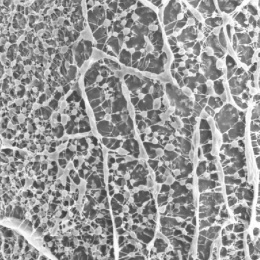

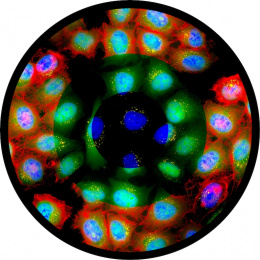

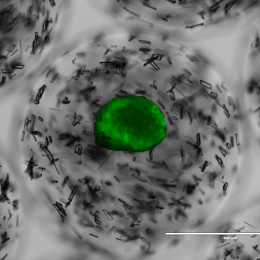

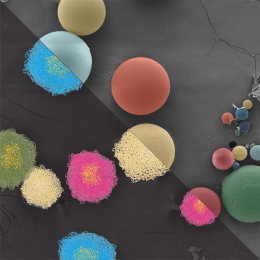

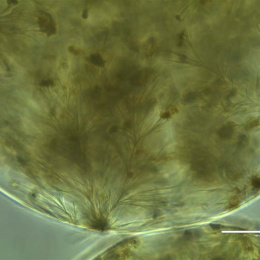

This is a 35 micron slice of a microparticle that was implanted under the skin of a mouse for one week before it was sectioned and imaged with a confocal microscope to study how the mouse’s immune system responded to it and whether there was any damage done to it. The microparticle was originally 300 x 300 x 100 microns, and it was constructed by a special microscale stamping, filling, and sealing process that was developed in the Langer Lab at MIT called SEAL (StampEd Assembly of Polymer Layers). It is an example of a “core shell” microparticle. The “shell” is comprised of a base and cap made of a biocompatible, biodegradable polymer called poly(lactic-co-glycolic) acid (PLGA). The hollow “core” of the microparticle can be filled with cargo such as vaccines or drugs. The microparticle is designed so that upon injection into the body, the PLGA will slowly degrade until eventually the cargo is released all at once. The time that it takes the polymer to degrade can be engineered to occur days, weeks, or even months after the microparticles are administered. Currently, these microparticles are being used to make single injection, self-boosting vaccines that can release their booster cargo at multiple timepoints in sequence many months after administration. They are also being used to deliver single injection, timed-release cancer therapeutics.